FoxAlien

[Flagship] CNC Router Machine CL-4x4

SKU: CNC-CL-4X4-US |

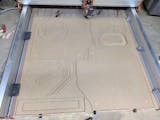

[Industrial Grade Flagship CNC] The CL-4x4 is the flagship CNC machine in the FoxAlien CNC family. It is built with the best industrial-grade hardware components, such as the HG-15 linear bearings on every axis, 16mm ball screws on the XY axis, and 12mm ball screws on the z-axis.

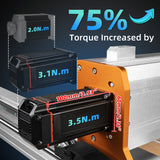

[Most Powerful Closed Loop Stepper Motors] The CL-4x4 comes with four Nema23(60-100) closed loop steppers. These four stepper motors have up to 3.5Nm torque, which has a 60% improvement when compared to the Vasto XXL and a 10% improvement when compared with the CL-6560.

[Fast Moving Speed] It is really important to have a fast-moving speed for a full-size CNC machine. Due to the high efficiency of the closed loop motors, the CL-4x4's max moving speed can reach 5000mm/min. This is 2.5 times faster than the Vasto XXL.

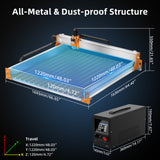

[Largest Working Area & Offline Control] The CL-4x4 has up to 122cm x 122cm x 10cm/ 48” x 48” x 3.94”(XYZ) working area, it can fit standard full-sized sheets without cutting them. Build in a 2.4-inch touchscreen on the controller box. This can control the machine without connecting to a PC.

[Easy Installation] The CL-4x4 will be shipped with 6 boxes. The main parts are pre-assembled, it just takes 30-45 minutes to assemble the machine, and then you can explore the journey of CNC machining.

Description

The CL-4x4 is the flagship CNC machine in the FoxAlien CNC family. It is built with the best industrial-grade hardware components, such as the HG-15 linear bearings on every axis, 16mm ball screws on the XY axis, 12mm ball screws on the z axis & the most powerful closed loop stepper motors. It has up to 122cm x 122cm x 10cm/ 48” x 48” x 3.94”(XYZ) working area, and it can fit standard full-sized sheets without cutting them.

Specification

- Working Table: T-slot Hybrid Table

- Cutting Area XYZ: 122cm x 122cm x 10cm/ 48” x 48” x 3.94”

- Spindle: 400W

- Router: Support 65mm and 69 Router, Makita RT0700C and DeWalt DWP611

- X Axis: 16mm Ball Screws & Linear Rails

- Y-Axis: 16mm Ball Screws & Linear Rails

- Z-Axis: 12mm Ball Screws & Linear Rails

- Stepper Motors: Nema23(60-100) Close Loop Stepper Motor

- Torque: 3.5Nm

- Independent Driver: DM542

- Machine Structure Material: All Metal

Package List

- 1x CNC router CL-4x4 (half-assembled in 6 boxes)

- 1x T-slot Hybrid Table

- 1x Controller

- 2x Set of engraving bits (10pcs/set)

- 1x USB cable

- 1x Power cord

- 1x Box of screws and tools

- 1x User manual

- 52mm & 65mm & 69mm spindle holder

![[Flagship] CNC Router Machine CL-4x4](http://www.foxalien.com/cdn/shop/files/Untitleddesign_dcc9347f-1f2f-4ea5-a804-b8778b280b61_{width}x.png?v=1695097134)

![[Flagship] CNC Router Machine CL-4x4](http://www.foxalien.com/cdn/shop/files/9_ed39dc28-133a-41be-8ecf-547c285a0beb_{width}x.jpg?v=1700642365)

![[Flagship] CNC Router Machine CL-4x4](http://www.foxalien.com/cdn/shop/files/10_54d14538-21db-43e9-ad21-82f847f0904a_{width}x.jpg?v=1700642365)

![[Flagship] CNC Router Machine CL-4x4](http://www.foxalien.com/cdn/shop/files/7_1_{width}x.jpg?v=1700642365)

![[Flagship] CNC Router Machine CL-4x4](http://www.foxalien.com/cdn/shop/files/1_1_eb0323d7-7779-421e-a4f2-740f4a542b14_{width}x.jpg?v=1700642365)

![[Flagship] CNC Router Machine CL-4x4](http://www.foxalien.com/cdn/shop/files/2_1_{width}x.jpg?v=1700642365)

![[Flagship] CNC Router Machine CL-4x4](http://www.foxalien.com/cdn/shop/files/5_1_{width}x.jpg?v=1700642365)

![[Flagship] CNC Router Machine CL-4x4](http://www.foxalien.com/cdn/shop/files/6_1_{width}x.jpg?v=1700642365)

![[Flagship] CNC Router Machine CL-4x4](http://www.foxalien.com/cdn/shop/files/8_1_{width}x.jpg?v=1700642365)